Grand Seiko is a distinctively Japanese luxury brand. The

focus has been decidedly un-Swiss. Where the Swiss focus on artistry,

marketing, and polishing, with a very few focusing on technology like Patek’s

Advanced Research ref. 5550 and Omega’s Si-14 escapement. This has been a very

successful as is proven by the 19.3 billion CHF export figure in 2011. The

Grand Seiko focus has been on long-term reliability, legibility, precision, and

beauty. We will go through what each of these mean for the Japanese as well as

compare the Grand Seiko 9S6X developed in 2011 with the 9S5X developed in 1998.

Patek ref. 5550 Advanced Research

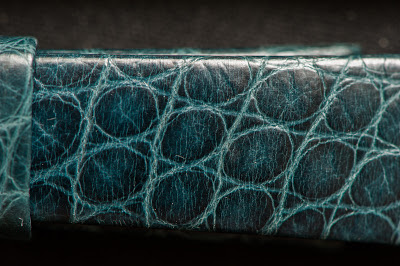

The Grand Seiko SBGM031 is very similar to the SBGM021

(Brown strap on Deployant/Tang) and SBGM023 (Solid stainless steel bracelet).

The differences are in the dial, hands, rotor, and strap. Of course, the

SBGM031 is also a limited edition of 1000 globally. 33 pieces went to the

United States and 3 went to China.

Basic specifications:

Manufacturer Caliber 9S66

Automatic, hand wind capable and hacking (stop seconds)

28.4mm diameter by 5.9mm thick

28,800 vph

72 hour power reserve on one barrel

Spron 610 hairspring and

MEMS manufactured escapement (pallet fork and escape wheel)

Tokyo stripe finish on rhodium plated brass

Diashock shock resistance

35 Jewels

Fully made in Japan

Dimensions are 39.5mm diameter and 13.5mm thickness

Sapphire crystal both sides (raised “box” style crystal with

antiglare on front)

3 atm water resistance

Zaratsu (blade) polished stainless steel with beveled lugs.

MSRP of 6,300 USD

The movement

The finishing can be clearly seen in the hand wond 9S64A movement

(Note: All changes apply to all 9S6X

movements compared to the 9S5X movements, i.e. 9S54, 9S55, 9S56 vs 9S64, 9S55,

9S66)

Winding system:

The new 9S66 caliber uses a small diameter, specially coated (like Rolex’s Teflon coating) reverser system for efficient winding while the 9S56 uses Seiko’s magic lever system. This may be due to the increase of power reserve from 55 to 72 hours requiring significantly more torque. The magic lever system has been known to slip under high torque.

New Reverser system

Previous magic lever pawl winding system (similar to IWC Pellaton)

Main plate finish:

The new 9S66 Caliber has perlage on the baseplate while the 9S65 has a sand blasted finish.

Balance staff:

Increase diameter from 0.07mm to 0.08mm resulting in 30% increase in strength.

Rotor (regular edition):

Slightly different shape and engraving

Calendar plate:

9S66 has the GS logo engraved throughout the plate (not visible unless dial is removed). Date size is slightly larger than the 9S56. Interestingly, both use four Philips screws to fasten the calendar plate.

Transmission wheel bridge:

Is now part of a solid bridge instead of a stamped sheet metal plate.

Power reserve increased from 55 to 72 hours. Thickness

increased from 5.4mm to 5.9mm.

Jewel count increased from 26 to 35 (for automatics only,

hand wound increased from 20 to 24).

Escapement now manufactured by MEMS process and is

skeletonized. Resulting in decreased weight and increased precision.

MEMS Escapement (Note the small pockets to hold oil on the escape wheel)

Under AFM (Atomic Force Microscopy)

A video courtsey of Mimotec Switzerland about UV-LIGA manufacturing: http://vimeo.com/48295052

From my tests, the movement has been very precise and strong

running.

Results are: (s/d deviation, amplitude, beat error, assuming lift angle of 52 degrees)

At full wind

Dial Up +5 278 0.1

Dial Down +2 273 0.1

Crown Left +3 255 0.0

Crown Right -2 256 0.2

Crown Down +4 255 0.0

Crown Up 0 262 0.1

After 8 hours

Dial Up +3 265 0.2

Dial Down +2 266 0.1

Crown Left +1 256 0.0

Crown Right -3 248 0.2

Crown Down +3 246 0.0

Crown Up -1 249 0.2

Patek's Oscillomax Silicon escapement

An interesting feature of the MEMS escapement is that it is

just as accurately manufactured as a silicon escapement used in Patek

Philippe’s Oscillomax escapement manufactured using Silinvar. However, the MEMS

escapement is still made with conventional alloys and thus does not feature the

antimagnetic properties of a fully silicon escapement. Also, ruby impulse

jewels are still used instead of a full silicon pallet fork. Unlike many Swiss

movements, the Seiko still uses an asymmetric screw regulator for a flat hairspring

instead of a free sprung balance using either gyromax or microtesla screws. The rate, however, is still very impressive

regardless. SII of Seiko Corporation actually manufacturers hairsprings for

many Swiss brands as an alternative to Nivarox.

The hardness of Seiko’s steel components is actually number

one in the industry today, at somewhere between 700-740 HV (Vickers), similar

to the 740 HV of vintage Pateks (note, this is speculative and very difficult to verify). The recent decrease in steel hardness by the

Swiss is unexplained, but may allow easier manufacturing of parts and less time

since such hardness is usually accomplished by ice tempering of steel (heated

to 1000 C, then quenched in 20 C oil, then frozen for -80 C for 1 hour, then

baked at 160 C for several hours).

The Tokyo Stripes finish is deeper than most Côte de

Genève style finishes and is highly reflective. The plates are not beveled and anglage is nowhere to be seen, but

the sides are nonetheless perfectly smooth. Flat components are all highly

polished to absolute flatness.

The Seiko manufacturing facility is also another reassurance

of quality movement manufacturing. SJX described in his visit here that the

cleanroom was a class 1000 (less than 1000 particles of 0.5μm size or larger) cleanroom, which has

1/35,000th the particle concentration of normal outdoor urban air.