The full auction results can be seen at Sotheby's here, there were only a few items within or below estimate.

Saturday, November 23, 2013

Sotheby's Jony and Marc's (RED) Auction shatters estimate (featuring a unique JLC Atmos and Memovox)

The full auction results can be seen at Sotheby's here, there were only a few items within or below estimate.

Wednesday, November 6, 2013

The results of the 2013 Concours international de chronométrie

The concours ended with somewhat disappointing results. Interestingly, Tissot beat everyone (and even many of the previous tourbillons) to win the top 2 in the non-tourbillon section. Even more disappointingly only one of the 7 tourbillon entires finished (entires from prestigious makers including Laurent Ferrier, Greubel Forsey, and L.U.C. Chopard did not even pass the torture tests).

Encouragingly, two of the twelve student entires (from Mathieu Douik and Maxime Bettenelli of CIFOM passed.

Full results are below (click to enlarge):

An absolute monster of accuracy (878 and 850 pts.) improving on their 764 pt 2011 result with the 2824.

Encouragingly, two of the twelve student entires (from Mathieu Douik and Maxime Bettenelli of CIFOM passed.

Full results are below (click to enlarge):

Tuesday, November 5, 2013

In another time: My Prodigy M mATX Hackintosh Gaming PC Build

So this blog is suppose to be about watches, but I have other interests too. And after contemplating for a long time I decided to build my own PC. Problem was, I'm a 8+ year old Mac user so switching back to windows was just too much to handle. Hacktintoshing was the only solution I saw, so without further ado...

The parts

I wanted something as compact as possible but also with enough expandability. The number one criteria, of course, was that the parts had to be hackintosh compatible without extensive intervention. I consulted the TonyMacX86 buyer's guide and ended up with the following:

PCPartPicker part list: http://pcpartpicker.com/p/1Y5bZ

Price breakdown by merchant: http://pcpartpicker.com/p/1Y5bZ/by_merchant/

Benchmarks: http://pcpartpicker.com/p/1Y5bZ/benchmarks/

CPU: Intel Core i5-4670K 3.4GHz Quad-Core Processor ($239.99 @ Newegg)

CPU Cooler: Noctua NH-U12S 55.0 CFM CPU Cooler ($68.71 @ Amazon)

Motherboard: Gigabyte GA-Z87MX-D3H Micro ATX LGA1150 Motherboard ($124.99 @ Newegg)

Memory: Crucial Ballistix Sport 8GB (2 x 4GB) DDR3-1600 Memory ($63.99 @ Newegg)

Storage: Crucial M4 256GB 2.5" Solid State Disk ($209.99 @ Adorama)

Storage: Seagate Momentus XT 750GB 2.5" 7200RPM Hybrid Internal Hard Drive ($149.99 @ Amazon)

Video Card: Gigabyte GeForce GTX 770 2GB Video Card ($334.99 @ NCIX US)

Case: BitFenix Prodigy M Arctic White MicroATX Mini Tower Case ($106.98 @ SuperBiiz)

Power Supply: Corsair Professional 750W 80 PLUS Gold Certified ATX12V / EPS12V Power Supply ($129.99 @ Newegg)

Operating System: Microsoft Windows 8.1 Pro - OEM (64-bit) ($139.98 @ OutletPC)

Total: $1547.60

(Prices include shipping, taxes, and discounts when available.)

(Generated by PCPartPicker 2013-11-05 22:45 EST-0500)

I also decided to add a second Noctua NF-F12, as well as 2 NF-P12 FLX fans for intake and a NF-P14 ULN for rear exhaust.

The build process:

It took me a very very long time to build this since this is my first build and I wanted to not break anything. Overclocking was also rather difficult and I ended up settling at a mere 4 GHz. The most difficult part is cable management, and here's a short list of tips to avoid mistakes that I made.

#1. Buy a 165 mm or shorter power supply, the HX750 Gold is 200 mm and has blocked out my only 16x PCIe 3.0 slot. The 770 or even 780 won't saturate PCIe 3.0 8x but I will need to get a new power supply when upgrading the graphics card.

#2. Can I SLI in the prodigy M (realistically). YES! But don't get too excited, on my particular motherboard you'll be running one card in x4 and the other in x16, also the intake fans at the top will definitely not fit and it will be even more crampted than it is now. But I have tried placing a MSI Gaming 770 into the top slot and yes, you can 2 way SLI.

#3. Flip the panels. What? Yes, flip the panels. Hardware canucks mentioned this in their overview of the Prodigy M case. Simply put the panel with the IO on the backplate side and the plain panel on the component side. This will allow for MUCH BETTER cable management.

#4: Get a reasonably sized cooler, the Noctua NH-U12S is probably the best fit here, in push pull only the pull fan is active at low loads, and it can push enough air to keep the CPU cool in a pretty tight space.

#5: You're going to have to reassemble a few times to get it right. The case is just too small to make the process straightforward. Want to add an intake fan? You'll need to remove the GPU and probably the heatsink.

#6: Have large hands? You'll either need to recruit someone with small or skinny hands for this build, plugging in the fan headers for the heatsink, threading cables through other cables, and doing anything in this case requires some serious manual dexterity.

And the result:

The parts

I wanted something as compact as possible but also with enough expandability. The number one criteria, of course, was that the parts had to be hackintosh compatible without extensive intervention. I consulted the TonyMacX86 buyer's guide and ended up with the following:

PCPartPicker part list: http://pcpartpicker.com/p/1Y5bZ

Price breakdown by merchant: http://pcpartpicker.com/p/1Y5bZ/by_merchant/

Benchmarks: http://pcpartpicker.com/p/1Y5bZ/benchmarks/

CPU: Intel Core i5-4670K 3.4GHz Quad-Core Processor ($239.99 @ Newegg)

CPU Cooler: Noctua NH-U12S 55.0 CFM CPU Cooler ($68.71 @ Amazon)

Motherboard: Gigabyte GA-Z87MX-D3H Micro ATX LGA1150 Motherboard ($124.99 @ Newegg)

Memory: Crucial Ballistix Sport 8GB (2 x 4GB) DDR3-1600 Memory ($63.99 @ Newegg)

Storage: Crucial M4 256GB 2.5" Solid State Disk ($209.99 @ Adorama)

Storage: Seagate Momentus XT 750GB 2.5" 7200RPM Hybrid Internal Hard Drive ($149.99 @ Amazon)

Video Card: Gigabyte GeForce GTX 770 2GB Video Card ($334.99 @ NCIX US)

Case: BitFenix Prodigy M Arctic White MicroATX Mini Tower Case ($106.98 @ SuperBiiz)

Power Supply: Corsair Professional 750W 80 PLUS Gold Certified ATX12V / EPS12V Power Supply ($129.99 @ Newegg)

Operating System: Microsoft Windows 8.1 Pro - OEM (64-bit) ($139.98 @ OutletPC)

Total: $1547.60

(Prices include shipping, taxes, and discounts when available.)

(Generated by PCPartPicker 2013-11-05 22:45 EST-0500)

I also decided to add a second Noctua NF-F12, as well as 2 NF-P12 FLX fans for intake and a NF-P14 ULN for rear exhaust.

The build process:

It took me a very very long time to build this since this is my first build and I wanted to not break anything. Overclocking was also rather difficult and I ended up settling at a mere 4 GHz. The most difficult part is cable management, and here's a short list of tips to avoid mistakes that I made.

#1. Buy a 165 mm or shorter power supply, the HX750 Gold is 200 mm and has blocked out my only 16x PCIe 3.0 slot. The 770 or even 780 won't saturate PCIe 3.0 8x but I will need to get a new power supply when upgrading the graphics card.

#2. Can I SLI in the prodigy M (realistically). YES! But don't get too excited, on my particular motherboard you'll be running one card in x4 and the other in x16, also the intake fans at the top will definitely not fit and it will be even more crampted than it is now. But I have tried placing a MSI Gaming 770 into the top slot and yes, you can 2 way SLI.

#3. Flip the panels. What? Yes, flip the panels. Hardware canucks mentioned this in their overview of the Prodigy M case. Simply put the panel with the IO on the backplate side and the plain panel on the component side. This will allow for MUCH BETTER cable management.

#4: Get a reasonably sized cooler, the Noctua NH-U12S is probably the best fit here, in push pull only the pull fan is active at low loads, and it can push enough air to keep the CPU cool in a pretty tight space.

#5: You're going to have to reassemble a few times to get it right. The case is just too small to make the process straightforward. Want to add an intake fan? You'll need to remove the GPU and probably the heatsink.

#6: Have large hands? You'll either need to recruit someone with small or skinny hands for this build, plugging in the fan headers for the heatsink, threading cables through other cables, and doing anything in this case requires some serious manual dexterity.

And the result:

Monday, September 9, 2013

Why is Rolex so expensive?

Relative to the cost of production, pretty much everything we own and use is "expensive." That 40 dollar cotton polo shirt costs a few dollars to make and transport. Louis Vuitton prices their products 13 to 15 times production cost (far above the 8-10x industry norm). This markup tends to be the greatest for luxury goods. But Rolex is expensive for many reasons beyond being a luxury product, a few of which I'll list.

1: Strong demand-Rolex is unarguably the automatic brand that the average consumer around the world will think of when it comes to luxury watches. This has made rolex a strong aspirational brand which many young professionals (yuppies) buy with their first cheque. The annual production is around 850,000 pieces a year with an average price somewhere around 7,000 USD.

2: Consistent design-With a few exceptions (like the leopard daytona) Rolex is very consistent in its designs. It has clearly delineated lines with easy to understand products. There are a few things that other watch brands vying for the crown could learn to stop doing. Excessive limited editions, special editions, explicit co-branding, heavy discounting, and strange advertising. There are only four brands that come to mind who conform to this standard: A. Lange & Söhne, Glashutte Original, Patek Philippe, and Rolex. Even the venerable Jaeger-LeCoultre has created the horrendous Navy Seal and Batman collaborations.

3: Consistent quality-This is much easier to achieve now with better technology, but through the ages Rolex hasn't turned to producing cheap quartz watches to stay afloat (it had Tudor to make the profit from the lower end market) which has preserved the brand's status.

4: Honest heritage/technical innovation-This is a bit mixed, but Rolex has a real history of being a reliable professional instrument before quartz watches. Rolex made the first waterproof (now legally called water resistant) watch, the first self-winding wristwatch (although self winding mechanisms are nothing new), the first helium release valve, and the first GMT movement. There are features we take for granted now and Rolex deserves honest recognition for these achievements. Another technical innovation they've put into mass production is the free sprung hairspring with breguet overcoil, along with the ceramic bezel: both features slowly being adopted by other brands.

The real reason Rolex is expensive is that we allow it to be, but with all the watch you get for your money, it's not overpriced. Hublot on the other hand...

Monday, August 19, 2013

Tissot PR 100 Automatic Review (Gents and Ladies)

Review of Tissot PR 100 (Ladies and men’s)

These two models from Tissot are really outside of my normal range of watches, but since I had the chances to handle them I was interested what 400-500 dollars could buy in the mechanical watch world. From my previous review of the Orient Mako we found what the Japanese had to offer at the 110 and 200-dollar levels. It can pretty much be summarized up as stamped clasp, stamped end link, in house roughly finished non-hacking automatic movement, and excellent value if you pick correctly. Now that we’ve gone to the Swiss, it can be expected you’ll get less value Surprisingly it seems that since the near-death experience of the quartz crisis, Le Locle has been able to get its act together and produce excellent value.

These two models from Tissot are really outside of my normal range of watches, but since I had the chances to handle them I was interested what 400-500 dollars could buy in the mechanical watch world. From my previous review of the Orient Mako we found what the Japanese had to offer at the 110 and 200-dollar levels. It can pretty much be summarized up as stamped clasp, stamped end link, in house roughly finished non-hacking automatic movement, and excellent value if you pick correctly. Now that we’ve gone to the Swiss, it can be expected you’ll get less value Surprisingly it seems that since the near-death experience of the quartz crisis, Le Locle has been able to get its act together and produce excellent value.

The first thing that appeals to me is the tame size of the

watches, the women’s is 27mm while the men’s is 37mm. The 37mm hits the sweet

spot for a dressier watch (I believe the optimal is between 35 and 38mm).

This review will apply to both the women’s and men’s version

of the PR 100 since the differences are only in the size and movement, which

I’ll comment on separately at the end.

Dial/Hands

The dial is surprisingly complex for a watch of this price,

while guilloche and blue hands are totally absent, the black dial has a crisp

circular brushed pattern, but upon careful observation, there is a hint of

brown which helps add depth to the dial. I’m not sure whether this is the brass

underneath showing through the paint or because the paint has is simply dark

brown, but it’s a nice touch.

The white printing is good but not flawless as the edges of

letters can be a bit rough. The applied markers are relatively plain but I have

no suspicion they’ll be falling off like those on a Canal street Rolex.

The hands are lumed (presumably with superluminova) but I

would count on reading it in the middle of the night. The overall layout is

good and without too much excessive clutter. The date is small but that’s the

nature of the small non-big date movement.

Case

The case is made of stainless steel, but I’m not sure if

it’s 316L or an alternative. But it feels solid, even the engraving on the

caseback is machined instead of laser engraved. Thankfully the retainer ring

(as viewed without opening the case) seems to be metal instead of plastic,

which helps with the feeling of the watch. The case is tastefully brushed with

a polished bezel and simply does its job quite nicely. A nice touch is the

slight space on the back of the case which really makes the crown much easier

to operate. One point of concern is that despite the supposed 100m water

resistance, the crown is not screw in and the case back appears to be snap on,

but I trust that these dress watches aren’t the watch of choice for COMEX.

Bracelet

Watches are like this is probably why my childhood dream

Rolex ownership ended in two weeks. The Rolex had hollow center bracelet links

and stamped end links, all while costing over 10 times as much. In fact the

Bracelet value alone could buy both the gent’s and ladies PR 100 with change to

spare to go on a dinner date wearing both. But I digress; the bracelet is made

of solid links with solid end links. The SEL should help the durability

immensely as stamped end links tend to deform with a few years of wear (they

can be repaired by bending them back in shape, but it’s not exactly preferred).

The removable links are held with pins, as is standard on lower priced watches.

Ironically, some think that expanded pins are more secure than the more

expensive and more upscale spring bars (for 5+ row bracelets) or screws: I tend

to agree while still preferring screws.

The clasp is stamped, but feels reasonably okay. Overall the

bracelet has a slightly loose feeling, but I see no reason why it wouldn’t be

durable. It just doesn’t feel extremely well finished.

Movement

While both movements can be considered “in-house”, they’re

arguably the most commonly found movements in any watch that claims to be swiss

made today. Unlike similarly priced watches from Japan, the movement has both

quick set date and has a hack seconds function. Strangely enough, the women’s

version has a slightly better finished movement, not that it counts for much.

The women’s ETA 2671 has a brushed finish on a few bridges while the men’s is

plainly matte throughout. Neither will qualify for the Poiçon de Geneve or the

Qualite Fleurier so finishing is a null point. The 2824 is a notably well

performing movement that actually won the Concours internationale de

chronometrie in 2011 for the non-tourbillon category. I’m sure the ETA 2671 is also

a well performing and rugged movement, but its smaller size makes it inherently

more fault prone.

ETA 2671 in the ladies model

Value

So it would seem that despite all the power that the “Swiss

Made” label has, a good value can still be had. The quality of the finish came

at a bit of a surprise to me, in a good way. It meets many more of the

criterion for a good watch than could be expected at the price point. Solid end

links, in-house movement, and sapphire crystals are all there. Would I

personally wear the watch? No. But I can still admire the excellent value it

represents. They’re still good looking watches, both of a reasonable diameter

and thickness, and also with tastefully executed bracelets. It’s a good daily

wearer, in the truest sense of the term.

Friday, July 19, 2013

Monday, July 1, 2013

A tour of the Hublot manufacturer in Nyon, Switzerland

Hublot is a bit of a controversial name in horology, my opinion of the brand has fluctuated from great admiration in my mid teens (when the big bang was introduced and heavily advertised) to mild contempt after discovering their movements were 7750 based. My current attitude is that the brand has every right to sell a product that was in great demand, but it's still got a bit to prove. The brand is currently around 350 employees producing 35,000 pieces a year and growing rapidly.

I was fortunate enough to visit the Hublot manufacturer last week in Nyon, Vaud canton about 15 minutes by train outside Geneva. The current factory was built in 2009 but the company has already outgrown the building and purchased another building for expansion. All operations take place in the building including movement production (from raw material to the finished movements), casing up, and quality control. Hublot does not make its own cases with the exception of the new ceramic based Magic Gold, and also buys (like almost all manufacturers) its sapphire crystals, straps, jewels, and clasps.

The first part of the building is filled with CNC machines and spark erosion machines used to produce watch parts. I did not notice any machines producing either small parts such as pinions and escapements or silicium parts but they could be elsewhere in the building, although my bet is that silicium parts are purchased from a supplier.

Since the brand focuses on "The art of fusion", many movement parts are made with carbon fiber and other novel materials.

Tucked in the back of the parts manufacture area is a room filled with autoclaves and other machines where Mr. Senad Hasanovic works on producing the new scratch resistant 18 karat magic gold, which is produced by making a ceramic tube that is 75% porous and then forcing pure gold into those spaces to produce 18k (750/1000) ceramic gold. The material behaves the same as ceramic, being extremely hard but slightly brittle. However, it appears like a dark gold alloy and is extremely dense. A new material, which could be named magic aluminium, will take the technique for magic gold but apply it to aluminium to produce a lightweight grey material.

Preassembly involved a semi-automated placing of jewels and small posts into movement parts. The parts are QC'd before being brought to the assembly area where the final watch is assembled. There is a single workshop for producing the in-house UNICO chronograph movement which features a modular escapement with silicium anchor and escape wheel. The movement is not free spring but the brand is certainly aware of the demand for free sprung balances and we may expect to see one in the future.

The haute horology workshop is in a separate area of the building where the brand's finest offerings are finished by hand and assembled by a single watchmaker. Two examples that I was shown are the skeleton tourbillon and minute repeater monopusher chronograph tourbillon.

Despite being rather judgmental about the brand previously, it's understandable that the brand is rapidly growing and there is no reason why it could not eventually produce its own cases and all movement parts. Hublot certainly knows its customers, and how to get even more, and that's an admirable quality in and of itself.

I was fortunate enough to visit the Hublot manufacturer last week in Nyon, Vaud canton about 15 minutes by train outside Geneva. The current factory was built in 2009 but the company has already outgrown the building and purchased another building for expansion. All operations take place in the building including movement production (from raw material to the finished movements), casing up, and quality control. Hublot does not make its own cases with the exception of the new ceramic based Magic Gold, and also buys (like almost all manufacturers) its sapphire crystals, straps, jewels, and clasps.

CNC machining of a mainplate

Machine mainplates, awaiting further treatment (finishing and plating)

Cut brass discs and complete mainplates

The first part of the building is filled with CNC machines and spark erosion machines used to produce watch parts. I did not notice any machines producing either small parts such as pinions and escapements or silicium parts but they could be elsewhere in the building, although my bet is that silicium parts are purchased from a supplier.

Steel parts made from wire-spark erosion

Parts made with wire-spark erosion (passing an ultra high voltage through an extremely thin metal wire)

The wire is the width of a human hair

Since the brand focuses on "The art of fusion", many movement parts are made with carbon fiber and other novel materials.

Tucked in the back of the parts manufacture area is a room filled with autoclaves and other machines where Mr. Senad Hasanovic works on producing the new scratch resistant 18 karat magic gold, which is produced by making a ceramic tube that is 75% porous and then forcing pure gold into those spaces to produce 18k (750/1000) ceramic gold. The material behaves the same as ceramic, being extremely hard but slightly brittle. However, it appears like a dark gold alloy and is extremely dense. A new material, which could be named magic aluminium, will take the technique for magic gold but apply it to aluminium to produce a lightweight grey material.

Material engineer Mr. Senad Hasanovic explains the process of Magic Gold.

Preassembly involved a semi-automated placing of jewels and small posts into movement parts. The parts are QC'd before being brought to the assembly area where the final watch is assembled. There is a single workshop for producing the in-house UNICO chronograph movement which features a modular escapement with silicium anchor and escape wheel. The movement is not free spring but the brand is certainly aware of the demand for free sprung balances and we may expect to see one in the future.

Semi-automatic jeweling operation

The operator places the correct sized jewel in each sink and the machine places them on the part

QC of jewleing operation

Hand driving of jewels for more limited production movements

Diagram of the modular UNICO escapement

Purple silicium escape wheel with stylized "H" spokes

Silicium anchor of the Unico movement

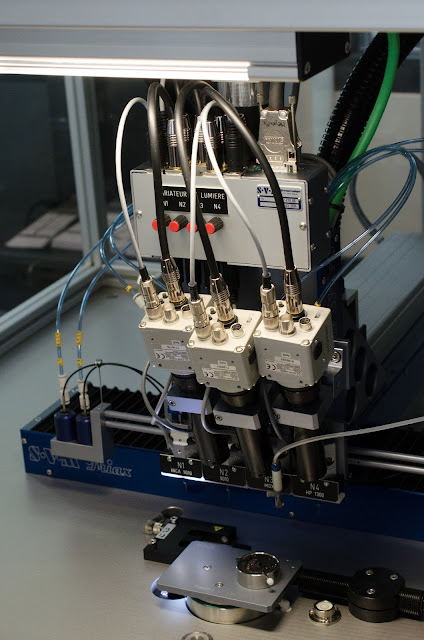

Automatic lubrication machine, applies the perfect quantity of oil on each oiling point

Grease for watch stems and a small pad for noting imperfections on watches

The haute horology workshop is in a separate area of the building where the brand's finest offerings are finished by hand and assembled by a single watchmaker. Two examples that I was shown are the skeleton tourbillon and minute repeater monopusher chronograph tourbillon.

Hand perlage in the haute horologerie workshop

Poising a balance wheel

Classic Fusion Skeleton Tourbillon Titanium

King Power Minute Repeater Chrono Tourbillon (48mm)

Despite being rather judgmental about the brand previously, it's understandable that the brand is rapidly growing and there is no reason why it could not eventually produce its own cases and all movement parts. Hublot certainly knows its customers, and how to get even more, and that's an admirable quality in and of itself.

Subscribe to:

Comments (Atom)